Your satisfaction is our pride.

PROCESS & QUALITY

PRODUCTION PROCESS

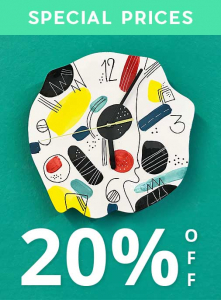

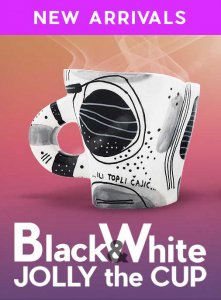

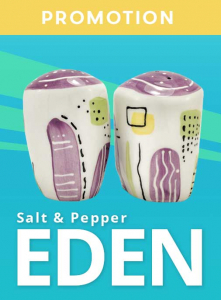

Every product Narteos produces comes with style. That means that behind every product there is a story and behind every story there is a plan of the production process that helps us to make the product we sell in high quality and unique. The production process is not simple and consists of a series of steps. Because we use our hands a lot, most products have slight deviations in shapes and colors. They are all unique. After the raw shaping of the clay, drying follows, where we must take care that the products do not dry too quickly. Drying is followed by sanding, after sanding, drying process again, followed by smoothing … Everything together consists of seventeen steps from first time we take the product in our hands till we guide it through five main stages of the process: shaping, drying, illustrating, double glazing and firing.

HIGH QUALITY of PRODUCTS

The reason why our products are of high quality is the material we use in the production (ceramics with chemically purified granules of ceramics that further strengthen it’s structure), double glazing of products that double strengthens the final layer on ceramics and firing clay in kiln (two times) up to highly 1150 ° C. For comparison, plain pottery is baked at 960 ° C and porcelain is baked at 1250 ° C.

Due to the height of the temperature, during firing process, the pores of the ceramics are compressed so much to 1150 ° C that you can easily put all our products in the dishwasher.

This highly resistant material the only things it is not resistant to are microwave, raging partner and solid concrete.